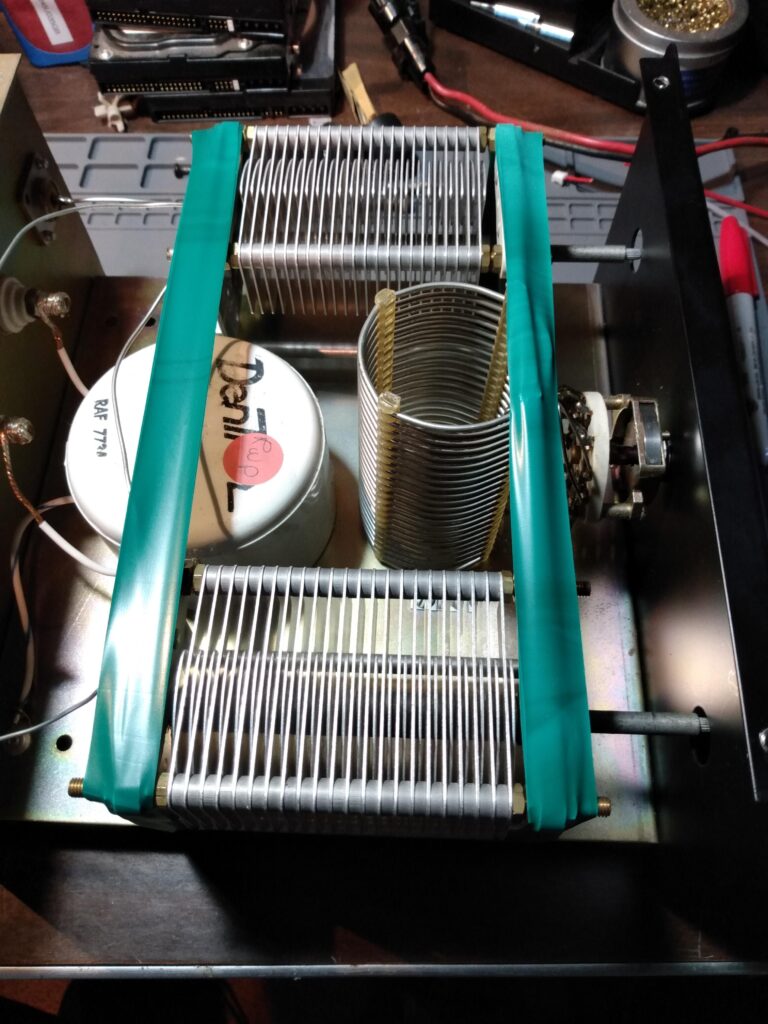

A few months ago I bought a 1KW Dentron Super Tuner antenna tuner from a friend. I didn’t really have a need for it, and these tuners lack modern conveniences like roller inductors and meters, but they are well reviewed and regarded as very capable for QRO under 1000 watts. I planned on bundling it with an amplifier at a hamfest, but it sold online before that could happen. I have no problem with this, because I’m perpetually out of room to store unused gear, and less gear cluttering my shack is a Good Thing.

I had a busy Monday, and lots of packages to drop off at the post office. As I hefted a large box of First Class Mail packages onto my shoulder, the box containing the tuner tumbled out of the backseat of the truck and hit the pavement with a BONK that could only be interpreted as catastrophic. I figured out how to transmute an antenna tuner into maracas.

I sell a lot of stuff on the internet, and as the sales director of American Light and Fixture’s shower curtain ring division, it’s my job to make sure customers are happy or I don’t get paid. I have the same philosophy when it comes to selling ham gear. So my #1 ham radio priority was to fix this.

I contacted the buyer and explained the situation, and they were fine with the tuner being repaired, as long as it worked. It turns out that dropping the tuner outside the post office may have been a blessing in disguise.

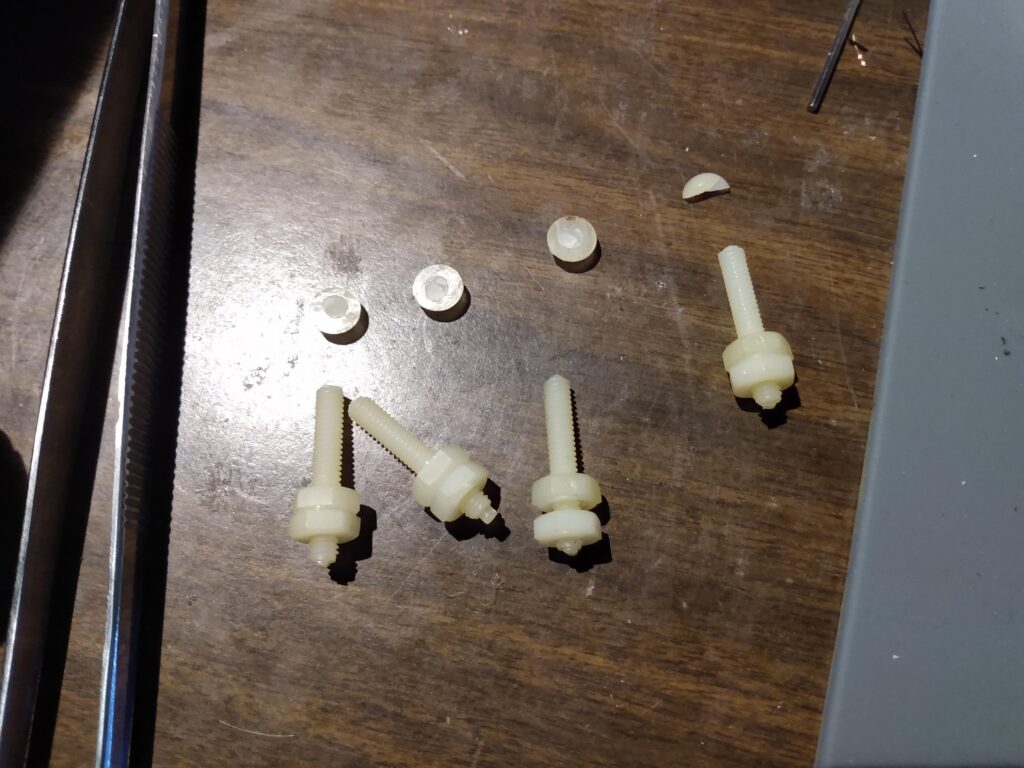

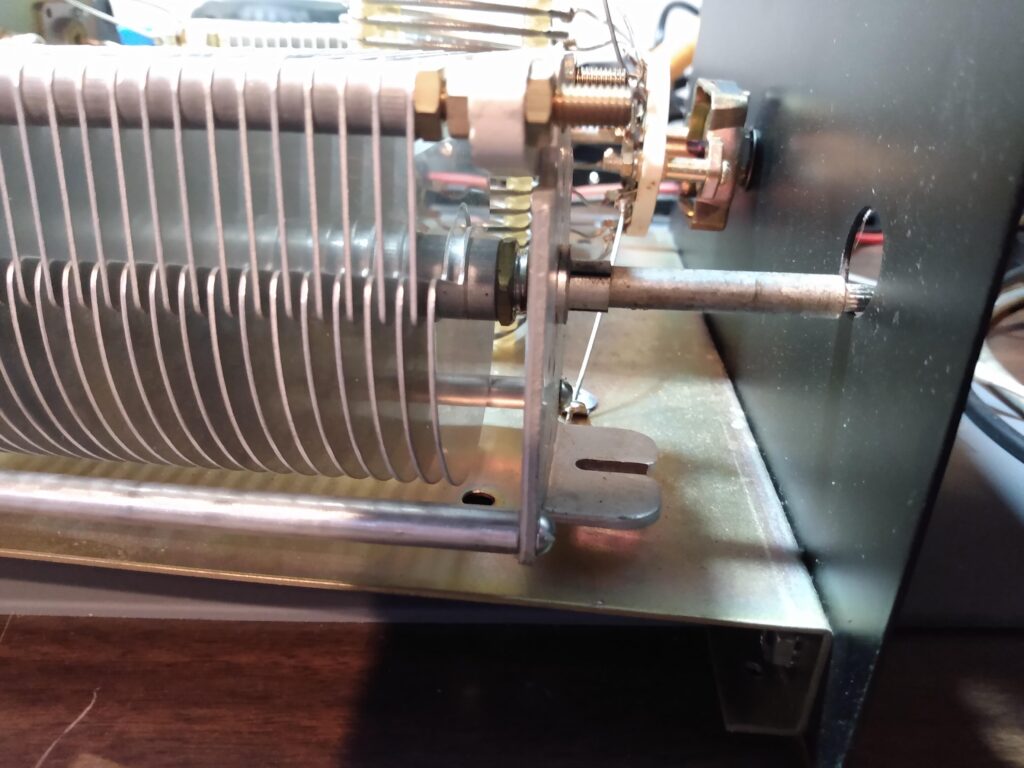

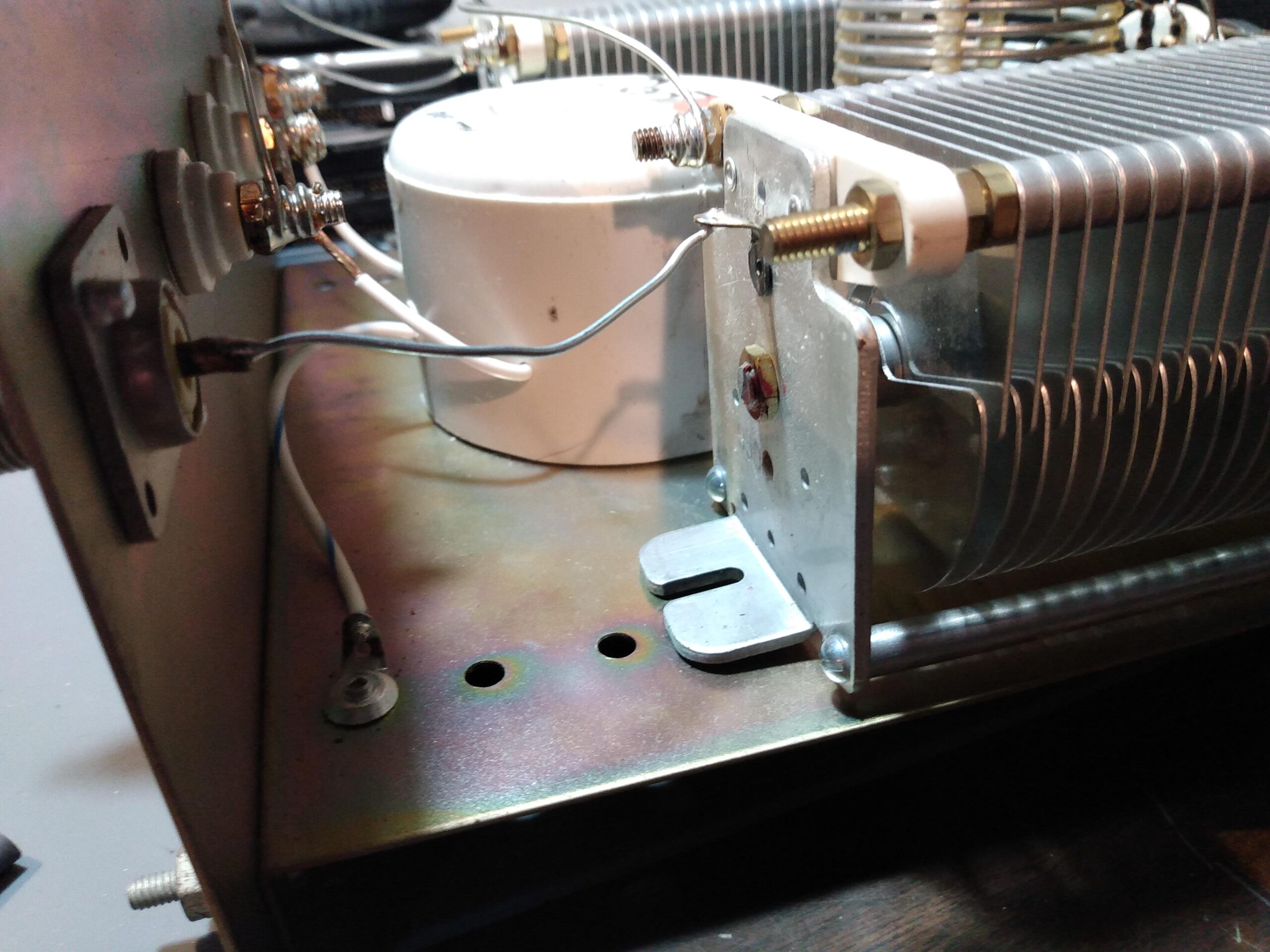

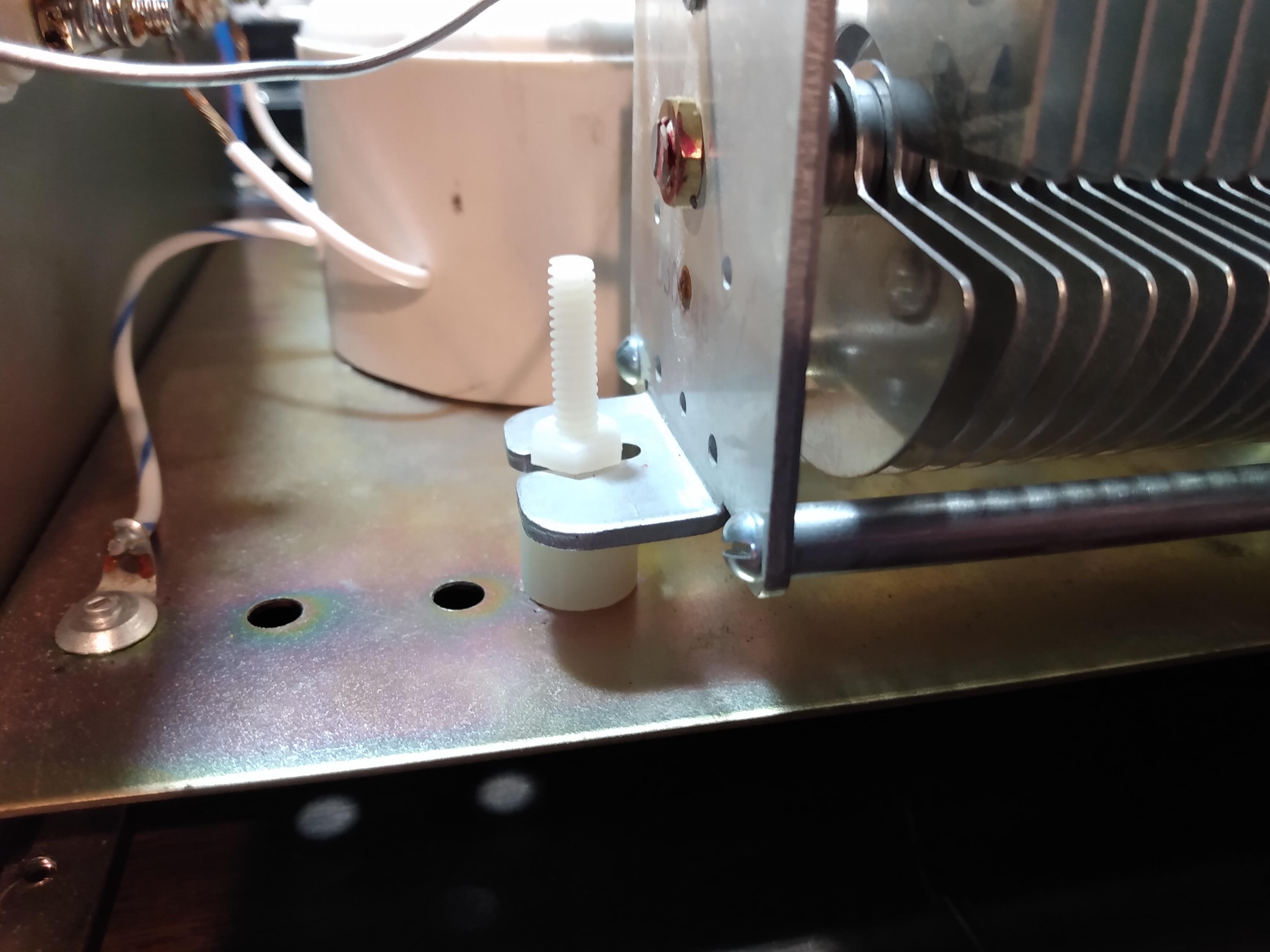

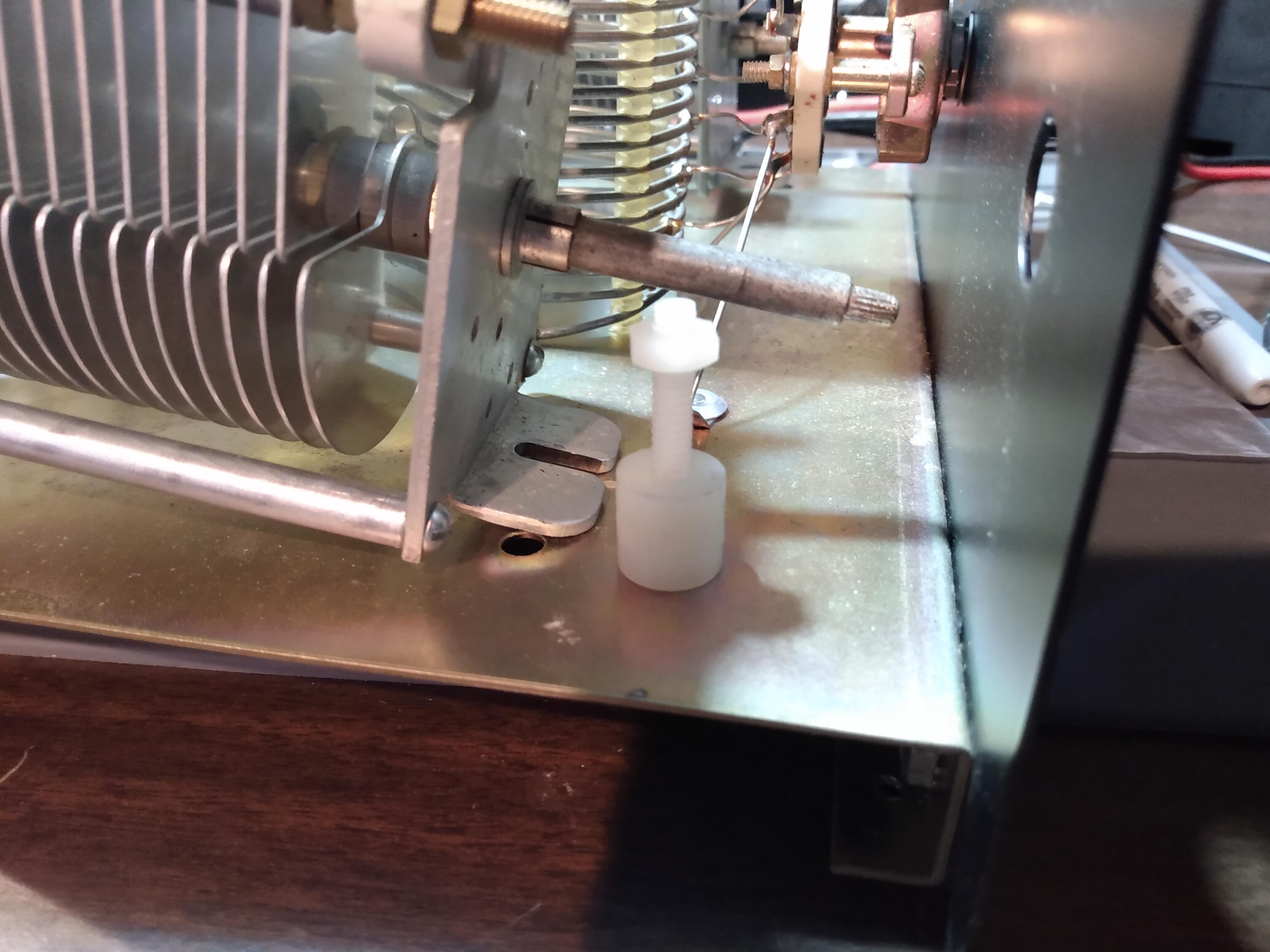

Electrically, the tuner was fine. But the two air capacitors inside the Dentron Super Tuner are isolated from the chassis ground by two pairs of nylon spacers and nuts/bolts. These bolts are what snapped when the tuner fell, and some light research concluded that this is a pretty common problem when shipping these Dentron tuners. The tuner was at least 40 years old, and the bolts were dry and brittle. Not surprising.

My first thought was to replace the mounting hardware with steel nuts and bolts, but my lizard brain said “there’s probably a reason they aren’t conductive,” and instinct was correct. The schematic for the Dentron Super Tuner shows that the air capacitors are not grounded to the chassis, because doing so would cause a short in the antenna system. I had to isolate them from the chassis or the tuner was useless.

The first hardware store I visited was pretty well-stocked, but apparently nobody knew that nylon hardware existed. The second was better stocked and had replacement parts that would work. I replaced those original dried and brittle nylon 8×32 nuts and bolts with slightly thicker 10×24 nylon parts. It was a tighter fit, but the thicker hardware decreased the possibility that these components would break under typical shipping stresses.

I couldn’t guarantee that the new parts wouldn’t break in transit, so I wrapped several courses of electrical tape around the air capacitors at each end to hold them to the chassis in case the bolts break again. I didn’t really expect the electrical tape to do much of of anything in the event of trauma, but anything that might keep them from bouncing around inside the chassis seemed helpful. I made sure to wrap the electrical tape so it does not interfere with the blades of the capacitors, so the buyer could leave it in place if they preferred.

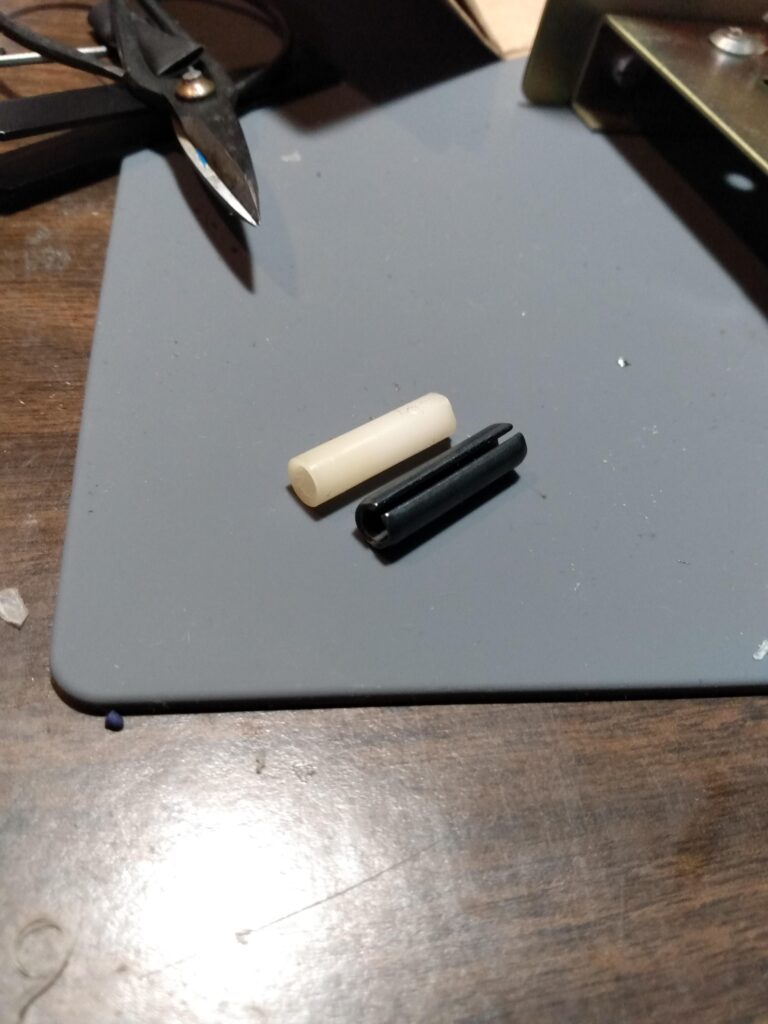

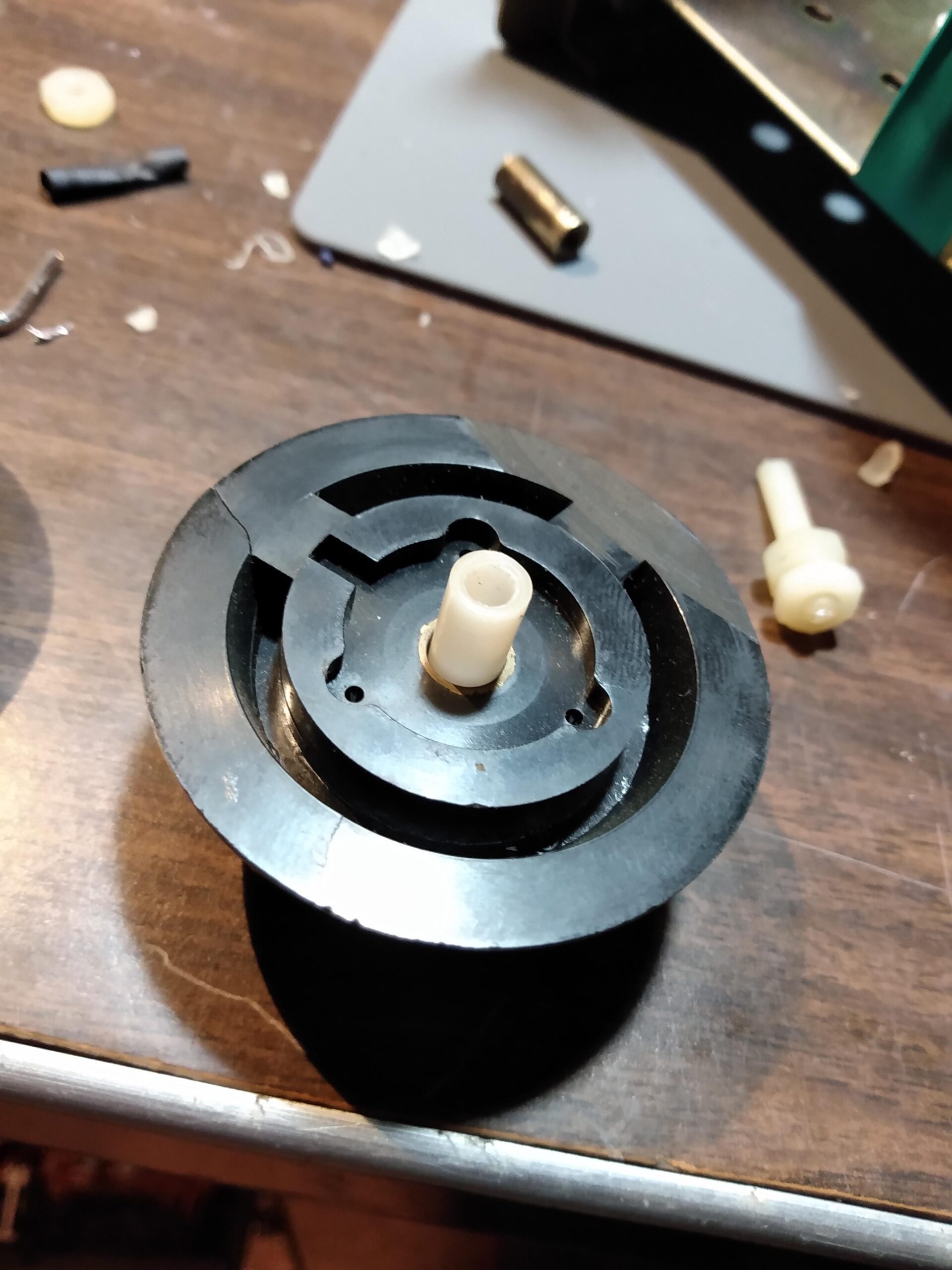

The other problem I uncovered was with one of the connections between the knob and the shaft of one of the air capacitors. The knobs for ANTENNA matching and TRANSMITTER matching are connected to the shafts of the variable capacitors with a 1/4″ nylon dowel drilled to press-fit onto the capacitor shaft, which is then held by the knob via a worm screw. Only one of these was present. The other knob was held in place with a 1/4″ brass fitting which was cross-threaded onto the shaft of the capacitor (poorly). If the tuner hadn’t been dropped, I wouldn’t have noticed this, but I suspect it would have come loose in transit.

Nylon nuts and bolts are hard enough to source, but 1/4″ nylon dowel is almost impossible to find in the hardware stores of Small Town, USA. I found a 1/4″ x 1″ steel roll pin that I attempted to use as a replacement, but it didn’t quite work. Luckily, friend and neighbor KC3MGN pulled some strings and was able to source a short piece of 1/4″ nylon dowel, which I then cut to length and drilled on one end to press fit onto the shaft of the capacitor. The result wasn’t visually perfect, but I challenge anybody using the tuner to tell the difference.

This project raised my blood pressure. But The Dentron Super Tuner is a better tuner after the damage than it was before, just because it brought these issues to my attention. If not for my butterfingers, it probably would have arrived damaged anyway. I suppose some things happen for a reason, and I hope the buyer gets a lot of use out of this tuner for many years to come.