Living on the floor of a valley in the Appalachian Mountains doesn’t make for very good day-to-day weak signal VHF operating. Normally I don’t bother doing 2 meter operation unless it’s talking to one of the nearby mountaintop repeaters. But the January and June VHF contests are the exception, and I take these opportunities to set up portable operation on a nearby ridge.

The contest didn’t start until 2PM local time, so I eased into my morning by drinking some coffee, working on some QBM, and working some 10 meter sideband DX before the North American QSO Party started.

I arrived at my operating location, the intersection of PA Route 554 and Skyline Drive, at precisely 1PM. I chose this location not because it is the best ridge to operate VHF from (I’m sure it’s not), but because it is only about 4 miles as the crow flies from my home station, is in the same grid square (FN11), and is about 1500 feet in elevation compared to 500 feet of elevation at my QTH on the valley floor.

Conditions were approximately 32 degrees and overcast, typical January weather in Pennsylvania. The area I operated from serves as a parking area for people utilizing the nearby hiking trails, so there were several cars taking up space. Luckily the owners of these cars emerged from the woods just as I was trying to figure out where to park, so I secured an ideal spot.

In the June 2022 VHF contest I had beams for 2 meters and 6 meters. My 6 meter beam isn’t really meant to be repeatedly broken down and transported, so I decided to stick to 2 meters for this trip. I was doing this portable operation alone and it would simplify setup and tear down.

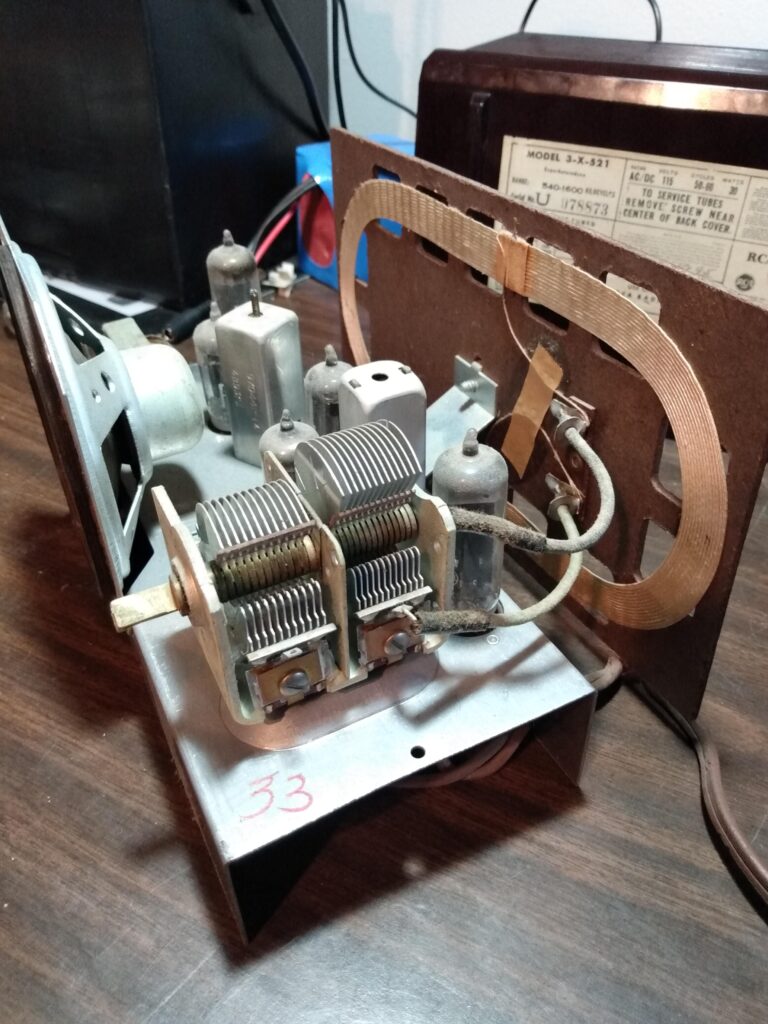

The antenna I use for 2 meters is an older Cushcraft 13B2 yagi that was generously given to me by Dale N3ZIO. When I received it, it was missing a couple elements, but MFJ was able to get them to me (eventually) for a few dollars each. It has 13 elements and provides 15.8 dBi of gain, a 26dB front-to-back ratio, and is about 15 feet long. It breaks down into 3 pieces for transport, which is just about perfect for fitting into the bed of my truck.

The mast the beam is mounted to is nothing more than a Harbor Freight telescoping flag pole with hose clamps to lock the sections in place. It’s not an elegant piece of hardware, but it was affordable and easily holds the weight of the beam. I should also mention that this particular mast’s bottom two sections are kind of stuck together, so actual height is only about 17 feet. This is fine for 2 meter work, since it puts the beam more than 2 full wavelengths above the ground. The plastic hooks on the mast (where a flag would normally attach) are excellent mounting points for guy lines, because they allow the mast to rotate, which means the beam can rotate as well.

The mast is held upright by a trailer hitch mast mount. The mount is long enough for the tailgate to be lowered with the mast in place, which makes mounting the beam to the mast very easy. I mounted the center section of the beam with the mast in its lowered position, attached the front and rear using a single stove bolt for each, connected the LMR400 coax to the antenna, and began raising the beam.

As I raised the beam, I also guyed it using paracord to two cleats at the front of the truck bed, and a tree directly behind the truck. I used some high visibility 3D printed paracord hooks to keep the lines tight. Surprisingly, there was no wind at this operating position so I would not have to stress test the limits of the paracord hooks. Perhaps another time.

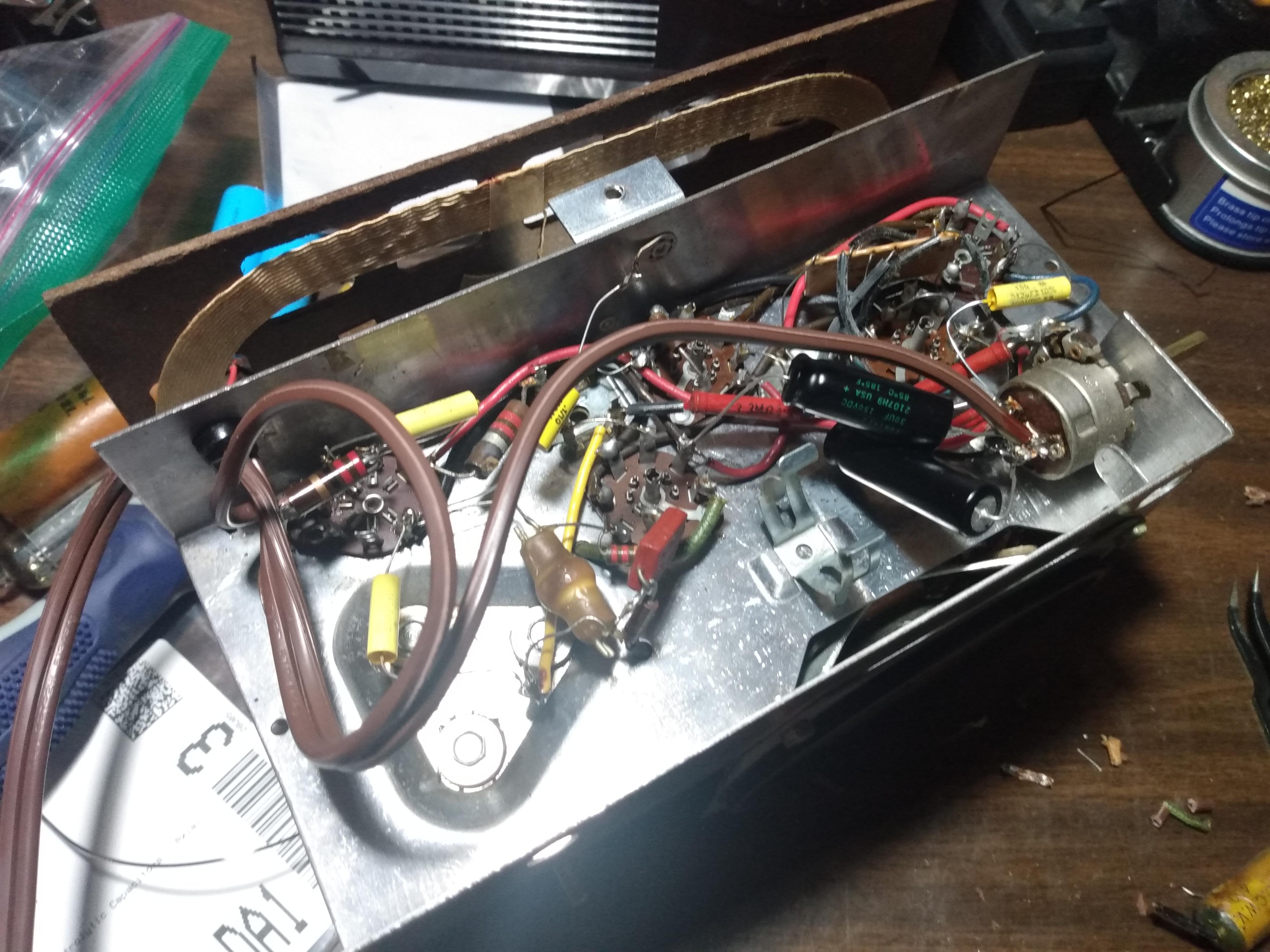

During the June VHF contest, I’ll set up a tent and a table and some chairs. January is a pretty unpleasant time to be outdoors in PA, so this time I decided to set up the operating position in the backseat of my truck. There is more than enough room for a small table, deep cycle marine battery, FT991a, and my laptop. I could run the heat in the truck and only have to get out to spin the beam.

The contest started promptly at 2PM. I was tuned to FT8 and immediately heard stations calling CQ. Dave KC3JNW was my first QSO on the very first contest-legal FT8 cycle. The first few minutes were a frenzy of the stations that could hear each other working each other, and it quickly slowed down.

I switched to SSB phone and worked a few stations, and then back to FT8 again. This cycle repeated a few times as the other stations moved between modes. I would hear a station on FT8, look them up on QRZ, point the beam in their general direction, and try to work them. I picked up a few stations this way.

A highlight of SSB phone was working Chris K2CR in two separate grid squares. As we had our second QSO, the clock struck 5PM and I decided it was time to pack up. My longest SSB QSO was either N2NT or K2CR at around 147 miles, and my longest FT8 QSO was to VA3IKE at 295 miles. Total was 27 FT8 QSOs (including a couple dupes) and 7 SSB QSOs, all on 2 meters. I am satisfied with these numbers.

Most FT8 QSOs were made with 25 watts, all SSB QSOs were made with 50w (maximum power on 2 meters with the FT991a). My deep cycle battery is a year old and does dip below 12v under load, but it had more than enough capacity to run the radio for 3 hours. I should start planning for its replacement.

I returned home at about 6PM and failed to make any QSOs on 6 meters. So I ended my evening casually S&Ping some NAQP SSB traffic on 20 and 40 meters.

One improvement I would like to make is adding an antenna switch and an omnidirectional 2 meter antenna. Working with only a beam can be difficult, and I don’t know how many stations I wasn’t hearing due to possible nulls in the pattern. I will ponder the antenna situation and come up with new experiments for June VHF.